Current Biotechnology ›› 2025, Vol. 15 ›› Issue (3): 518-525.DOI: 10.19586/j.2095-2341.2025.0006

• Articles • Previous Articles Next Articles

Optimization of Fermentation Culture Conditions for Cyclosporine A Using Response Surface Method

Xiaojing GAO( ), Zhulan ZHANG(

), Zhulan ZHANG( ), Xianju LIN, Guanrong QIU, Yaoming WEN, Jianhui FAN, Hongxiang HUANG

), Xianju LIN, Guanrong QIU, Yaoming WEN, Jianhui FAN, Hongxiang HUANG

- Fujian Provincial Key Laboratory of Screening for Novel Microbial Products,Fujian Institute of Microbiology,Fuzhou 350007,China

-

Received:2025-01-20Accepted:2025-02-28Online:2025-05-25Published:2025-07-01 -

Contact:Zhulan ZHANG

基于响应面法优化环孢菌素A发酵工艺的研究

高晓晶( ), 张祝兰(

), 张祝兰( ), 林仙菊, 邱观荣, 温耀明, 范建辉, 黄洪祥

), 林仙菊, 邱观荣, 温耀明, 范建辉, 黄洪祥

- 福建省微生物研究所,福州 350007

-

通讯作者:张祝兰 -

作者简介:高晓晶 E-mail: tju_gaoxiaojing@163.com; -

基金资助:福建省公益类科研院所专项(2023R1005002)

CLC Number:

Cite this article

Xiaojing GAO, Zhulan ZHANG, Xianju LIN, Guanrong QIU, Yaoming WEN, Jianhui FAN, Hongxiang HUANG. Optimization of Fermentation Culture Conditions for Cyclosporine A Using Response Surface Method[J]. Current Biotechnology, 2025, 15(3): 518-525.

高晓晶, 张祝兰, 林仙菊, 邱观荣, 温耀明, 范建辉, 黄洪祥. 基于响应面法优化环孢菌素A发酵工艺的研究[J]. 生物技术进展, 2025, 15(3): 518-525.

share this article

| 编码 | 组分 | 水平 | |

|---|---|---|---|

| -1 | 1 | ||

| A | 玉米浆粉/% | 3 | 6 |

| B | 麦芽糊精/% | 8 | 14 |

| C | 葡萄糖/% | 0.5 | 1.5 |

| D | 酵母浸粉/% | 0.1 | 0.2 |

| E | PEG200/% | 0.1 | 0.5 |

| F | 发酵时间/% | 7 | 10 |

| G | 硫酸铵/% | 0.1 | 1.0 |

| H | 发酵温度/℃ | 24 | 26 |

Table 1 The design of each variable in the PBD experiment

| 编码 | 组分 | 水平 | |

|---|---|---|---|

| -1 | 1 | ||

| A | 玉米浆粉/% | 3 | 6 |

| B | 麦芽糊精/% | 8 | 14 |

| C | 葡萄糖/% | 0.5 | 1.5 |

| D | 酵母浸粉/% | 0.1 | 0.2 |

| E | PEG200/% | 0.1 | 0.5 |

| F | 发酵时间/% | 7 | 10 |

| G | 硫酸铵/% | 0.1 | 1.0 |

| H | 发酵温度/℃ | 24 | 26 |

| 因素 | 编码 | 水平 | ||

|---|---|---|---|---|

| -1 | 0 | 1 | ||

| 玉米浆粉/% | X1 | 4 | 6 | 8 |

| 硫酸铵/% | X2 | 0.1 | 0.2 | 0.3 |

| 发酵时间/d | X3 | 9 | 10 | 11 |

| 葡萄糖/% | X4 | 0.4 | 0.6 | 0.8 |

Table 2 Factor design of the CCD experiment

| 因素 | 编码 | 水平 | ||

|---|---|---|---|---|

| -1 | 0 | 1 | ||

| 玉米浆粉/% | X1 | 4 | 6 | 8 |

| 硫酸铵/% | X2 | 0.1 | 0.2 | 0.3 |

| 发酵时间/d | X3 | 9 | 10 | 11 |

| 葡萄糖/% | X4 | 0.4 | 0.6 | 0.8 |

| 编号 | A | B | C | D | E | F | G | H | CsA含量/(mg·mL-1) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 5.42 |

| 2 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | -1 | 6.69 |

| 3 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 6.53 |

| 4 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 1 | 5.63 |

| 5 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 1 | 7.45 |

| 6 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 6.91 |

| 7 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | -1 | 7.65 |

| 8 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 6.19 |

| 9 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 1 | 7.10 |

| 10 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 11.44 |

| 11 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 10.89 |

| 12 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | -1 | 7.02 |

Table 3 PBD experimental design and results

| 编号 | A | B | C | D | E | F | G | H | CsA含量/(mg·mL-1) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 5.42 |

| 2 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | -1 | 6.69 |

| 3 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | -1 | 6.53 |

| 4 | 1 | 1 | 1 | -1 | -1 | -1 | 1 | 1 | 5.63 |

| 5 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 1 | 7.45 |

| 6 | -1 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | 6.91 |

| 7 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | -1 | 7.65 |

| 8 | -1 | 1 | -1 | 1 | 1 | -1 | 1 | 1 | 6.19 |

| 9 | -1 | -1 | -1 | 1 | -1 | 1 | 1 | 1 | 7.10 |

| 10 | 1 | 1 | -1 | 1 | 1 | 1 | -1 | -1 | 11.44 |

| 11 | 1 | 1 | -1 | -1 | -1 | 1 | -1 | 1 | 10.89 |

| 12 | -1 | 1 | 1 | 1 | -1 | -1 | -1 | -1 | 7.02 |

| 来源 | 平方和 | 自由度 | 均方 | F值 | P值 |

|---|---|---|---|---|---|

| 模型 | 37.39 | 8 | 4.67 | 9.87 | 0.043 |

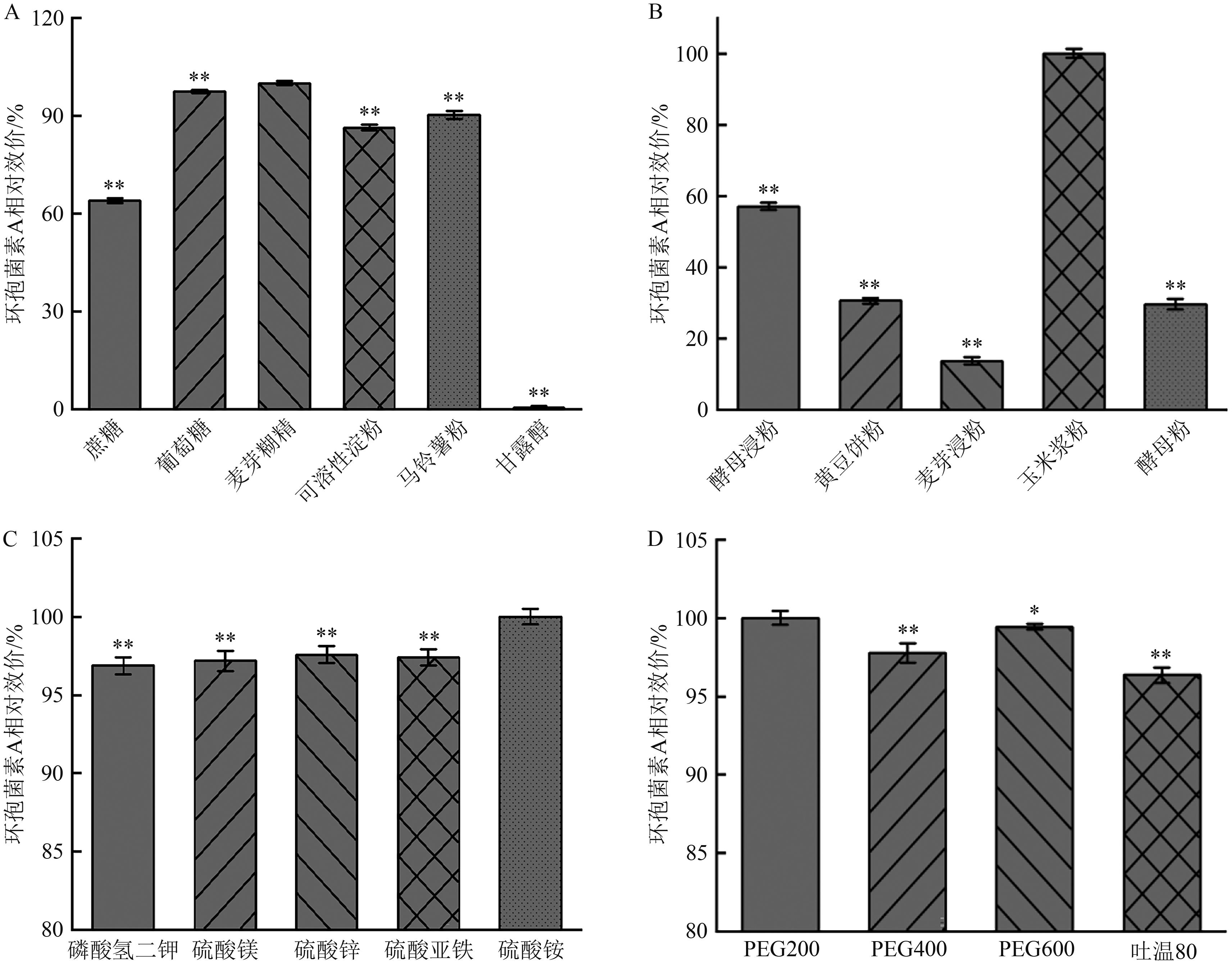

| A-玉米浆粉 | 9.32 | 1 | 9.32 | 19.68 | 0.021 3 |

| B-麦芽糊精 | 4.36 | 1 | 4.36 | 9.22 | 0.056 |

| C-葡萄糖 | 6.39 | 1 | 6.39 | 13.49 | 0.034 9 |

| D-酵母浸粉 | 1.91 | 1 | 1.91 | 4.03 | 0.138 4 |

| E-PEG200 | 0.045 4 | 1 | 0.045 4 | 0.095 8 | 0.777 2 |

| F-发酵时间 | 8.18 | 1 | 8.18 | 17.27 | 0.025 3 |

| G-硫酸铵 | 6.13 | 1 | 6.13 | 12.94 | 0.036 8 |

| H-发酵温度 | 1.06 | 1 | 1.06 | 2.24 | 0.231 4 |

| 残差 | 1.42 | 3 | 0.473 5 | ||

| 总和 | 38.81 | 11 |

Table 4 Analysis of variance in PBD

| 来源 | 平方和 | 自由度 | 均方 | F值 | P值 |

|---|---|---|---|---|---|

| 模型 | 37.39 | 8 | 4.67 | 9.87 | 0.043 |

| A-玉米浆粉 | 9.32 | 1 | 9.32 | 19.68 | 0.021 3 |

| B-麦芽糊精 | 4.36 | 1 | 4.36 | 9.22 | 0.056 |

| C-葡萄糖 | 6.39 | 1 | 6.39 | 13.49 | 0.034 9 |

| D-酵母浸粉 | 1.91 | 1 | 1.91 | 4.03 | 0.138 4 |

| E-PEG200 | 0.045 4 | 1 | 0.045 4 | 0.095 8 | 0.777 2 |

| F-发酵时间 | 8.18 | 1 | 8.18 | 17.27 | 0.025 3 |

| G-硫酸铵 | 6.13 | 1 | 6.13 | 12.94 | 0.036 8 |

| H-发酵温度 | 1.06 | 1 | 1.06 | 2.24 | 0.231 4 |

| 残差 | 1.42 | 3 | 0.473 5 | ||

| 总和 | 38.81 | 11 |

| 编号 | 玉米浆粉/% | 葡萄糖/% | 硫酸铵/% | 发酵时间/d | CsA含量/(mg·mL-1) |

|---|---|---|---|---|---|

| 1 | 3 | 1.2 | 0.3 | 7 | 8.48 |

| 2 | 4 | 1.0 | 0.25 | 8 | 10.66 |

| 3 | 5 | 0.8 | 0.2 | 9 | 10.90 |

| 4 | 6 | 0.6 | 0.20 | 10 | 11.53 |

| 5 | 7 | 0.4 | 0.15 | 11 | 8.62 |

| 6 | 8 | 0.2 | 0.10 | 12 | 6.69 |

| 7 | 9 | 0 | 0.05 | 13 | 6.51 |

Table 5 Steepest ascent experimental design and results

| 编号 | 玉米浆粉/% | 葡萄糖/% | 硫酸铵/% | 发酵时间/d | CsA含量/(mg·mL-1) |

|---|---|---|---|---|---|

| 1 | 3 | 1.2 | 0.3 | 7 | 8.48 |

| 2 | 4 | 1.0 | 0.25 | 8 | 10.66 |

| 3 | 5 | 0.8 | 0.2 | 9 | 10.90 |

| 4 | 6 | 0.6 | 0.20 | 10 | 11.53 |

| 5 | 7 | 0.4 | 0.15 | 11 | 8.62 |

| 6 | 8 | 0.2 | 0.10 | 12 | 6.69 |

| 7 | 9 | 0 | 0.05 | 13 | 6.51 |

| 实验编号 | X1 | X2 | X3 | X4 | CsA含量/(mg·mL-1) |

|---|---|---|---|---|---|

| 1 | 1 | 2 | -1 | 1 | 8.94 |

| 2 | 0 | 0 | 0 | 0 | 11.92 |

| 3 | -1 | 1 | -1 | 1 | 8.84 |

| 4 | 1 | -1 | 2 | 1 | 10.60 |

| 5 | 0 | 2 | 0 | 0 | 10.57 |

| 6 | -1 | -1 | 1 | 1 | 10.31 |

| 7 | 0 | -2 | 0 | 0 | 10.12 |

| 8 | -2 | 0 | 0 | 0 | 7.12 |

| 9 | 0 | 0 | 0 | 0 | 11.93 |

| 10 | -1 | 1 | 1 | 1 | 9.59 |

| 11 | 2 | 0 | 0 | 0 | 7.87 |

| 12 | 1 | -1 | -1 | -1 | 9.65 |

| 13 | 0 | 0 | -2 | 0 | 8.75 |

| 14 | 1 | 1 | 1 | -1 | 10.14 |

| 15 | 0 | 0 | 0 | -2 | 10.04 |

| 16 | 0 | 0 | 0 | 0 | 11.77 |

| 17 | 0 | 0 | 0 | 0 | 11.30 |

| 18 | -1 | -1 | -1 | -1 | 9.71 |

| 19 | -1 | 1 | -1 | -1 | 9.57 |

| 20 | -1 | -1 | 1 | -1 | 10.50 |

| 21 | 1 | -1 | 1 | -1 | 10.92 |

| 22 | 0 | 0 | 2 | 0 | 11.23 |

| 23 | 1 | 1 | 1 | 1 | 10.90 |

| 24 | -1 | -1 | -1 | 1 | 9.86 |

| 25 | 1 | -1 | -1 | 1 | 9.78 |

| 26 | 0 | 0 | 0 | 0 | 11.55 |

| 27 | 0 | 0 | 0 | 2 | 10.15 |

| 28 | 1 | 1 | -1 | -1 | 8.30 |

| 29 | 0 | 0 | 0 | 0 | 11.91 |

| 30 | -1 | 1 | 1 | -1 | 10.31 |

Table 6 The results of CCD

| 实验编号 | X1 | X2 | X3 | X4 | CsA含量/(mg·mL-1) |

|---|---|---|---|---|---|

| 1 | 1 | 2 | -1 | 1 | 8.94 |

| 2 | 0 | 0 | 0 | 0 | 11.92 |

| 3 | -1 | 1 | -1 | 1 | 8.84 |

| 4 | 1 | -1 | 2 | 1 | 10.60 |

| 5 | 0 | 2 | 0 | 0 | 10.57 |

| 6 | -1 | -1 | 1 | 1 | 10.31 |

| 7 | 0 | -2 | 0 | 0 | 10.12 |

| 8 | -2 | 0 | 0 | 0 | 7.12 |

| 9 | 0 | 0 | 0 | 0 | 11.93 |

| 10 | -1 | 1 | 1 | 1 | 9.59 |

| 11 | 2 | 0 | 0 | 0 | 7.87 |

| 12 | 1 | -1 | -1 | -1 | 9.65 |

| 13 | 0 | 0 | -2 | 0 | 8.75 |

| 14 | 1 | 1 | 1 | -1 | 10.14 |

| 15 | 0 | 0 | 0 | -2 | 10.04 |

| 16 | 0 | 0 | 0 | 0 | 11.77 |

| 17 | 0 | 0 | 0 | 0 | 11.30 |

| 18 | -1 | -1 | -1 | -1 | 9.71 |

| 19 | -1 | 1 | -1 | -1 | 9.57 |

| 20 | -1 | -1 | 1 | -1 | 10.50 |

| 21 | 1 | -1 | 1 | -1 | 10.92 |

| 22 | 0 | 0 | 2 | 0 | 11.23 |

| 23 | 1 | 1 | 1 | 1 | 10.90 |

| 24 | -1 | -1 | -1 | 1 | 9.86 |

| 25 | 1 | -1 | -1 | 1 | 9.78 |

| 26 | 0 | 0 | 0 | 0 | 11.55 |

| 27 | 0 | 0 | 0 | 2 | 10.15 |

| 28 | 1 | 1 | -1 | -1 | 8.30 |

| 29 | 0 | 0 | 0 | 0 | 11.91 |

| 30 | -1 | 1 | 1 | -1 | 10.31 |

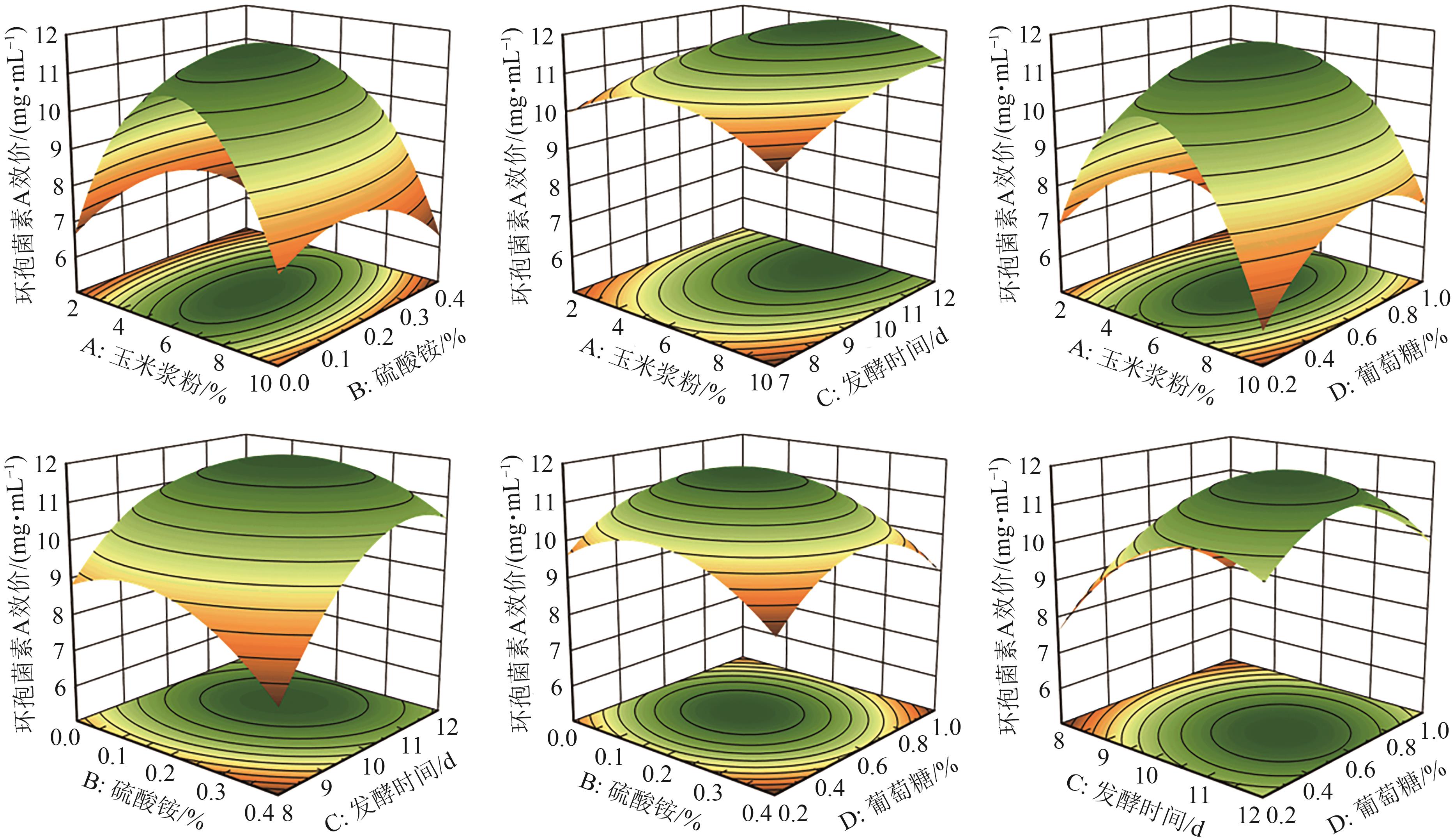

| 来源 | 平方和 | 自由度 | 均方 | F值 | P值 | |

|---|---|---|---|---|---|---|

| 模型 | 39.52 | 14 | 2.82 | 14.37 | <0.000 1 | ** |

| X1-玉米浆粉 | 0.17 | 1 | 0.17 | 0.87 | 0.366 5 | |

| X2-硫酸铵 | 0.62 | 1 | 0.62 | 3.14 | 0.096 7 | |

| X3-发酵时间 | 7.68 | 1 | 7.68 | 39.08 | <0.000 1 | ** |

| X4-葡萄糖 | 0.000 1 | 1 | 0.000 1 | 0.000 6 | 0.981 3 | |

| X1X2 | 0.02 | 1 | 0.02 | 0.12 | 0.734 8 | |

| X1X3 | 0.63 | 1 | 0.63 | 3.18 | 0.094 7 | |

| X1X4 | 0.45 | 1 | 0.45 | 2.29 | 0.150 6 | |

| X2X3 | 0.24 | 1 | 0.24 | 1.22 | 0.286 4 | |

| X2X4 | 0.002 4 | 1 | 0.002 | 0.01 | 0.913 0 | |

| X3X4 | 0.03 | 1 | 0.028 | 0.14 | 0.709 1 | |

| X12 | 27.11 | 1 | 27.11 | 138.04 | <0.000 1 | ** |

| X22 | 2.19 | 1 | 2.19 | 11.16 | 0.004 5 | ** |

| X32 | 3.77 | 1 | 3.77 | 19.20 | 0.000 5 | ** |

| X42 | 3.26 | 1 | 3.26 | 16.61 | 0.001 0 | ** |

| 残差 | 2.95 | 15 | 0.20 | |||

| 失拟项 | 2.62 | 10 | 0.26 | 3.96 | 0.070 9 | |

| 纯误差 | 0.33 | 5 | 0.066 | |||

| 总和 | 42.47 | 29 |

Table 7 Analysis of variance for the regression model

| 来源 | 平方和 | 自由度 | 均方 | F值 | P值 | |

|---|---|---|---|---|---|---|

| 模型 | 39.52 | 14 | 2.82 | 14.37 | <0.000 1 | ** |

| X1-玉米浆粉 | 0.17 | 1 | 0.17 | 0.87 | 0.366 5 | |

| X2-硫酸铵 | 0.62 | 1 | 0.62 | 3.14 | 0.096 7 | |

| X3-发酵时间 | 7.68 | 1 | 7.68 | 39.08 | <0.000 1 | ** |

| X4-葡萄糖 | 0.000 1 | 1 | 0.000 1 | 0.000 6 | 0.981 3 | |

| X1X2 | 0.02 | 1 | 0.02 | 0.12 | 0.734 8 | |

| X1X3 | 0.63 | 1 | 0.63 | 3.18 | 0.094 7 | |

| X1X4 | 0.45 | 1 | 0.45 | 2.29 | 0.150 6 | |

| X2X3 | 0.24 | 1 | 0.24 | 1.22 | 0.286 4 | |

| X2X4 | 0.002 4 | 1 | 0.002 | 0.01 | 0.913 0 | |

| X3X4 | 0.03 | 1 | 0.028 | 0.14 | 0.709 1 | |

| X12 | 27.11 | 1 | 27.11 | 138.04 | <0.000 1 | ** |

| X22 | 2.19 | 1 | 2.19 | 11.16 | 0.004 5 | ** |

| X32 | 3.77 | 1 | 3.77 | 19.20 | 0.000 5 | ** |

| X42 | 3.26 | 1 | 3.26 | 16.61 | 0.001 0 | ** |

| 残差 | 2.95 | 15 | 0.20 | |||

| 失拟项 | 2.62 | 10 | 0.26 | 3.96 | 0.070 9 | |

| 纯误差 | 0.33 | 5 | 0.066 | |||

| 总和 | 42.47 | 29 |

| 组别 | CsA含量/(mg·mL-1) |

|---|---|

| 初始组 | 7.95±0.72 |

| 预测组 | 11.87±0.18* |

| 验证组 | 11.76±0.47* |

Table 8 Results of the verification test (n=5)

| 组别 | CsA含量/(mg·mL-1) |

|---|---|

| 初始组 | 7.95±0.72 |

| 预测组 | 11.87±0.18* |

| 验证组 | 11.76±0.47* |

| 1 | PATOCKA J, NEPOVIMOVA E, KUCA K, et al.. Cyclosporine A: chemistry and toxicity-a review[J]. Curr. Med. Chem., 2021, 28(20): 3925-3934. |

| 2 | 郑孝贤. 多孔木霉菌的菌丝形态分化与环孢菌素A合成关系的初步研究[J]. 生物技术进展, 2013, 3(2): 140-144. |

| ZHENG X X. The relationship between morphological differentiation and cyclosporin a synthesis in Tolypocladium niveum [J]. Curr. Biotechnol., 2013, 3(2): 140-144. | |

| 3 | CUI W, CHEN S, HU T, et al.. Nanoceria-mediated cyclosporin a delivery for dry eye disease management through modulating immune-epithelial crosstalk[J]. ACS Nano, 2024, 18(17): 11084-11102. |

| 4 | HATAYA Y, NOMURA T, FUJISHIMA Y, et al.. Development of chronic thyroiditis during cyclosporin a treatment[J/OL]. JCEM Case Rep., 2024, 2(12): luae211[2025-04-22]. . |

| 5 | BABU P, PATEL Y, PANY S, et al.. Study of physiological parameters and rheology for the production and extraction of cyclosporin A[J]. Int. J. Res. Appl. Sci. Eng. Technol., 2022, 10(4): 394-399. |

| 6 | PANDEY S, TRIPATHI P, GUPTA A, et al.. A comprehensive review on possibilities of treating psoriasis using dermal cyclosporine[J]. Drug Deliv. Transl. Res., 2022, 12(7): 1541-1555. |

| 7 | SURVASE S A, KAGLIWAL L D, ANNAPURE U S, et al.. Cyclosporin A: a review on fermentative production, downstream processing and pharmacological applications[J]. Biotechnol. Adv., 2011, 29(4): 418-435. |

| 8 | 姜俊云, 董惠钧, 闫同顺. 雪白白僵菌产环孢菌素A分批补料发酵动力学[J]. 食品与发酵工业, 2012, 38(4): 53-56. |

| JIANG J Y, DONG H J, YAN T S. Fed-batch fermentation kinetics of cyclosporine a by Beauveria nivea [J]. Food Ferment. Ind., 2012, 38(4): 53-56. | |

| 9 | 戴梦, 刘静, 赵颖, 等. 环孢菌素A生产菌原生质体转化系统的建立[J]. 化学与生物工程, 2013, 30(3): 36-38. |

| DAI M, LIU J, ZHAO Y, et al.. Construction of protoplasts transformation system for cyclosporin a industrial strain[J]. Chem. Bioeng., 2013, 30(3): 36-38. | |

| 10 | 彭婷, 江丹, 陈阳, 等. 响应面法优化桑叶提取液脱色工艺及其对α-葡萄糖苷酶抑制活性[J]. 食品与发酵科技, 2024, 60(6):62-69. |

| PENG T, JIANG D, CHEN Y, et al.. Optimization of decolorization process of mulberry leaf extract using response surface methodology and its inhibitory activity on α-glucosidase[J]. Food Ferment. Sci. Technol., 2024, 60(6): 62-69. | |

| 11 | 张春丹, 乔洁, 解春艳, 等. 响应面法优化山楂皮渣总黄酮提取工艺及抗氧化活性研究[J]. 廊坊师范学院学报(自然科学版), 2024, 24(4): 49-55. |

| ZHANG C D, QIAO J, XIE C Y, et al.. Optimization ethanol extraction of total flavonoids from hawthorn pomace by response surface methodology and antioxidant activity[J]. J. Langfang Norm. Univ. Nat. Sci. Ed., 2024, 24(4): 49-55. | |

| 12 | 徐广新, 杨仁琴, 周炜, 等. 响应面法优化桂花酒酿酸奶制备工艺[J]. 食品安全质量检测学报, 2024, 15(23): 145-151. |

| XU G X, YANG R Q, ZHOU W, et al.. Optimization of preparation process of Osmanthus yoghurt with fermented glutinous rice by response surface methodology[J]. J. Food Saf. Qual., 2024, 15(23): 145-151. | |

| 13 | 梁子昌, 陈明, 李大宁, 等. 响应面法优化牛大力茎总黄酮提取工艺[J]. 化学与生物工程, 2024, 41(12): 30-35. |

| LIANG Z C, CHEN M, LI D N, et al.. Optimization in extraction process of total flavonoids from Millettia speciosa Champ.stem by response surface methodology[J]. Chem. Bioeng., 2024, 41(12): 30-35. | |

| 14 | 王喜龙, 张丽蓉, 欧晓彬, 等. 响应面法优化紫苏叶中抑菌成分的提取工艺[J]. 化学与生物工程, 2024, 41(12): 36-43. |

| WANG X L, ZHANG L R, OU X B, et al.. Optimization in extraction process of bacteriostatic components from Perilla leaves by response surface methodology[J]. Chem. Bioeng., 2024, 41(12): 36-43. | |

| 15 | 林仙菊, 张祝兰, 严凌斌, 等. ARTP诱变选育环孢菌素A高产菌株及发酵工艺优化[J]. 工业微生物, 2023, 53(4): 158-163. |

| LIN X J, ZHANG Z L, YAN L B, et al.. Study on screening of high-yield cyclosporin a producing strain by atmospheric and room temperature plasma mutagenesis and optimization of fermentation conditions[J]. Ind. Microbiol., 2023, 53(4): 158-163. | |

| 16 | 严凌斌, 张祝兰, 张引, 等. 响应面法优化他克莫司发酵培养基中无机盐组合[J]. 中国抗生素杂志, 2020, 45(10): 994-999. |

| YAN L B, ZHANG Z L, ZHANG Y, et al.. Optimization of inorganic salts of fermentation medium for tacrolimus production by response surface methodology[J]. Chin. J. Antibiot., 2020, 45(10): 994-999. | |

| 17 | 祃栋猛, 陆信曜, 陈文强, 等. 发酵后期补加2种氮源对克雷伯氏菌合成1,3-丙二醇的影响[J]. 食品与发酵工业, 2016, 42(8): 8-12. |

| MA D M, LU X Y, CHEN W Q, et al.. Influences on the biosynthesis of 1, 3-propanediol in Klebsiella pneumonia by feeding two types of nitrogen source at the late stage of fermentation[J]. Food Ferment. Ind., 2016, 42(8): 8-12. | |

| 18 | 卫云路, 郑成, 宁正祥. 表面活性剂作为发酵促进剂的国内外研究进展[J]. 化工进展, 2008, 27(7): 983-989. |

| WEI Y L, ZHENG C, NING Z X. Research progress of surfactants as fermentation accelerator[J]. Chem. Ind. Eng. Prog., 2008, 27(7): 983-989. | |

| 19 | 周丽, 石彦鹏, 牛春, 等. 环孢菌素A的诱变育种及其发酵工艺优化研究[J]. 中兽医医药杂志, 2021, 40(2): 19-22. |

| ZHOU L, SHI Y P, NIU C, et al.. Study on mutation breeding and fermentation optimization of cyclosporin A[J]. J. Tradit. Chin. Vet. Med., 2021, 40(2): 19-22. | |

| 20 | FALAH F, MORTAZAVI SALI, DANESH A, et al.. Production of cyclosporin A by Tolypocladium inflatum using dairy waste medium: optimization and investigation of the effect of ultrasound, high hydrostatic pressure, and pulsed electric field treatments on the morphology of fungus[J]. Biomass Convers. Biorefin., 2024, 14(22): 29101-29113. |

| 21 | 刘雨, 王会会, 赵建辉, 等. 雪白白僵菌高产环孢菌素A发酵条件优化[J]. 发酵科技通讯, 2021, 50(4): 198-201. |

| LIU Y, WANG H H, ZHAO J H, et al.. Optimization of fermentation conditions for high production of cyclosporin A from Beauvcria nivea [J]. Bull. Ferment. Sci. Technol., 2021, 50(4): 198-201. | |

| 22 | 张梦菲, 余炼, 李菲, 等. 响应面法优化暹罗芽孢杆菌产大环内酯的发酵培养条件[J]. 生物技术通报, 2024, 40(8): 299-308. |

| ZHANG M F, YU L, LI F, et al.. Optimization of fermentation culture conditions for macrolactins yield of Bacillus siamensis using response surface methodology[J]. Biotechnol. Bull., 2024, 40(8): 299-308. | |

| 23 | 孔蒙蒙, 金静静, 卢鹏, 等. 高产纤维素酶工程菌株产酶条件优化[J]. 生物技术进展, 2024, 14(6): 1032-1041. |

| KONG M M, JIN J J, LU P, et al.. Optimization of enzyme production conditions of high-yielding cellulase engineering strains[J]. Curr. Biotechnol., 2024, 14(6): 1032-1041. |

| [1] | Lihua ZHANG, Yifan WANG, Xuyang ZHANG, Qianying LIU, Siqi GAO, Jian JIAO. Optimization of Enzymatic Extraction Process of Salidroside by Response Surface Analysis [J]. Current Biotechnology, 2023, 13(3): 441-448. |

| [2] | Lei LIU, Xinyue ZHOU, Zhen ZHU, Ye CAO, Wenbin WANG. Prokaryotic Expression of Outer Membrane Ferritin Receptor pvuA Gene of Vibrio parahaemolyticus and Optimization of Induction Conditions for Product [J]. Current Biotechnology, 2022, 12(3): 396-404. |

| [3] | Chunyue ZHANG, Jiayang JIN, Yongjun QIU, Liqiang FAN, Liming ZHAO. Collision Between Tradition and Future: Technology and Application Progress in Food Fermentation Engineering [J]. Current Biotechnology, 2021, 11(4): 418-429. |

| [4] | HU Qinhan, WANG Wei, LUO Yingbiao, DU Fang, YANG Liuqing, ZHAO Ting* . Optimization of Ultrasonic Assisted Enzymatic Extraction of Polysaccharide from Kadsura longipedunculata by Response Surface Analysis [J]. Curr. Biotech., 2018, 8(4): 351-357. |

| [5] | ZHENG Daheng1,2, WANG Wei2, LI Qian2, CHEN Yao3, ZHANG Weijie2, ZHAO Ting4, YANG Liuqing4*. Optimization on Extraction Technology of Polysaccharides from Hibiscus sabdariffa by Response Surface Methodology and Evaluation of its Antioxidant Activity [J]. Curr. Biotech., 2018, 8(2): 161-168. |

| [6] | DENG Chunmeng1, LI Qian2, WANG Wei2, ZHANG Weijie2, YU Ping3, MAO Guanghua1*, ZHAO Ting3, FENG Weiwei1, YANG Liuqing3, WU Xiangyang1*. Optimization of Extraction of Water-soluble Selenium-containing Protein from Se-enriched Maitake by Response Surface Methodology [J]. Curr. Biotech., 2017, 7(3): 247-252. |

| [7] | REN Hong-mei, LIU Zuo-jun*, WU Guo-qiang, SHAN Xi-wen. Study on CMCase Production of Trichoderma W2 by Solid-state Fermentation [J]. Curr. Biotech., 2013, 3(4): 270-276. |

| [8] | ZHENG Xiao-xian. The Relationship Between Morphological Differentiation and Cyclosporin A Synthesis in Tolypocladium niveum [J]. Curr. Biotech., 2013, 3(2): 140-144. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||