Current Biotechnology ›› 2024, Vol. 14 ›› Issue (2): 287-294.DOI: 10.19586/j.2095-2341.2023.0125

• Articles • Previous Articles Next Articles

Optimization of Preparation Technology of Lactiplantibacillus plantarum HCS03-001 Freeze-dried Powder and its Anti-Helicobacter pylori Function

Haitao WANG1,2( ), Jia SONG1,2, Ping YU1,2(

), Jia SONG1,2, Ping YU1,2( ), Xuejiao CHEN1,2

), Xuejiao CHEN1,2

- 1.Jiangxi Renren Health Microecological Technology Co. ,Ltd. ,Jiangxi Zhangshu 331200,China

2.Renren Microbial Technology Research (Shenyang) Co. ,Ltd. ,Shenyang 110170,China

-

Received:2023-10-17Accepted:2024-02-04Online:2024-03-25Published:2024-04-17 -

Contact:Ping YU

植物乳植杆菌HCS03-001冻干粉制备工艺优化及抗幽门螺杆菌的功效

汪海涛1,2( ), 宋佳1,2, 余萍1,2(

), 宋佳1,2, 余萍1,2( ), 陈雪娇1,2

), 陈雪娇1,2

- 1.江西仁仁健康微生态科技有限公司,江西 樟树 331200

2.仁仁微生物科技研究(沈阳)有限公司,沈阳 110170

-

通讯作者:余萍 -

作者简介:汪海涛 E-mail: 724312941@qq.com;

CLC Number:

Cite this article

Haitao WANG, Jia SONG, Ping YU, Xuejiao CHEN. Optimization of Preparation Technology of Lactiplantibacillus plantarum HCS03-001 Freeze-dried Powder and its Anti-Helicobacter pylori Function[J]. Current Biotechnology, 2024, 14(2): 287-294.

汪海涛, 宋佳, 余萍, 陈雪娇. 植物乳植杆菌HCS03-001冻干粉制备工艺优化及抗幽门螺杆菌的功效[J]. 生物技术进展, 2024, 14(2): 287-294.

share this article

| 因素 | 水平 | |

|---|---|---|

| -1 | 1 | |

| 发酵温度/℃ | 35 | 36 |

| 发酵时间/h | 8 | 12 |

| 初始pH | 6.0 | 6.3 |

| 接种量/% | 1 | 3 |

| 冻干保护剂添加比例 | 1∶1 | 1:2 |

| 冻干时间/h | 40 | 42 |

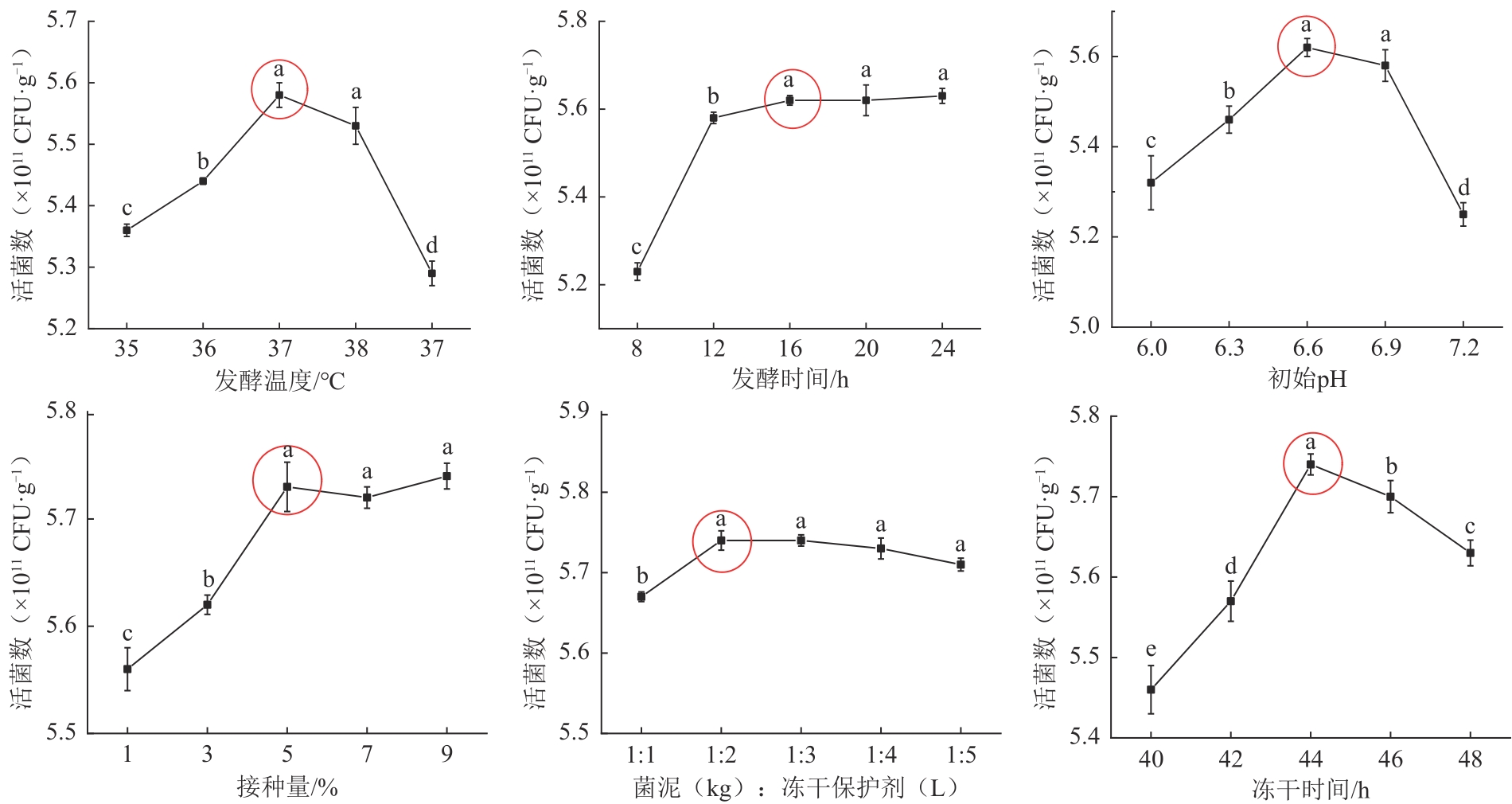

Table 1 Factors and level design of Plackett-Burman test

| 因素 | 水平 | |

|---|---|---|

| -1 | 1 | |

| 发酵温度/℃ | 35 | 36 |

| 发酵时间/h | 8 | 12 |

| 初始pH | 6.0 | 6.3 |

| 接种量/% | 1 | 3 |

| 冻干保护剂添加比例 | 1∶1 | 1:2 |

| 冻干时间/h | 40 | 42 |

| 因素 | 水平 | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| 发酵温度/℃ | 36 | 37 | 38 |

| 发酵时间/h | 12 | 16 | 24 |

| 接种量/% | 3 | 5 | 7 |

| 冻干时间/h | 42 | 44 | 46 |

Table 2 Horizontal coding table of Box-Behnken design factors

| 因素 | 水平 | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| 发酵温度/℃ | 36 | 37 | 38 |

| 发酵时间/h | 12 | 16 | 24 |

| 接种量/% | 3 | 5 | 7 |

| 冻干时间/h | 42 | 44 | 46 |

| 实验编号 | 发酵温度/℃ | 发酵时间/h | 初始pH | 接种量/% | 冻干保护剂 | 冻干时间/h | 活菌数/(×1011 CFU·g-1) |

|---|---|---|---|---|---|---|---|

| 1 | -1 | -1 | -1 | -1 | -1 | -1 | 5.46 |

| 2 | -1 | 1 | -1 | -1 | -1 | 1 | 5.31 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 5.18 |

| 4 | 1 | 1 | 1 | -1 | 1 | 1 | 5.11 |

| 5 | 1 | 1 | -1 | 1 | 1 | -1 | 5.06 |

| 6 | -1 | -1 | -1 | 1 | 1 | 1 | 4.87 |

| 7 | 1 | 1 | -1 | 1 | -1 | -1 | 5.25 |

| 8 | 1 | -1 | 1 | -1 | -1 | -1 | 5.29 |

| 9 | -1 | -1 | 1 | 1 | 1 | -1 | 5.33 |

| 10 | -1 | 1 | 1 | -1 | 1 | -1 | 5.02 |

| 11 | 1 | -1 | -1 | -1 | 1 | 1 | 5.33 |

| 12 | -1 | 1 | 1 | 1 | -1 | 1 | 5.26 |

Table 3 Design and results of Plackett-Burman experiment

| 实验编号 | 发酵温度/℃ | 发酵时间/h | 初始pH | 接种量/% | 冻干保护剂 | 冻干时间/h | 活菌数/(×1011 CFU·g-1) |

|---|---|---|---|---|---|---|---|

| 1 | -1 | -1 | -1 | -1 | -1 | -1 | 5.46 |

| 2 | -1 | 1 | -1 | -1 | -1 | 1 | 5.31 |

| 3 | 1 | -1 | 1 | 1 | -1 | 1 | 5.18 |

| 4 | 1 | 1 | 1 | -1 | 1 | 1 | 5.11 |

| 5 | 1 | 1 | -1 | 1 | 1 | -1 | 5.06 |

| 6 | -1 | -1 | -1 | 1 | 1 | 1 | 4.87 |

| 7 | 1 | 1 | -1 | 1 | -1 | -1 | 5.25 |

| 8 | 1 | -1 | 1 | -1 | -1 | -1 | 5.29 |

| 9 | -1 | -1 | 1 | 1 | 1 | -1 | 5.33 |

| 10 | -1 | 1 | 1 | -1 | 1 | -1 | 5.02 |

| 11 | 1 | -1 | -1 | -1 | 1 | 1 | 5.33 |

| 12 | -1 | 1 | 1 | 1 | -1 | 1 | 5.26 |

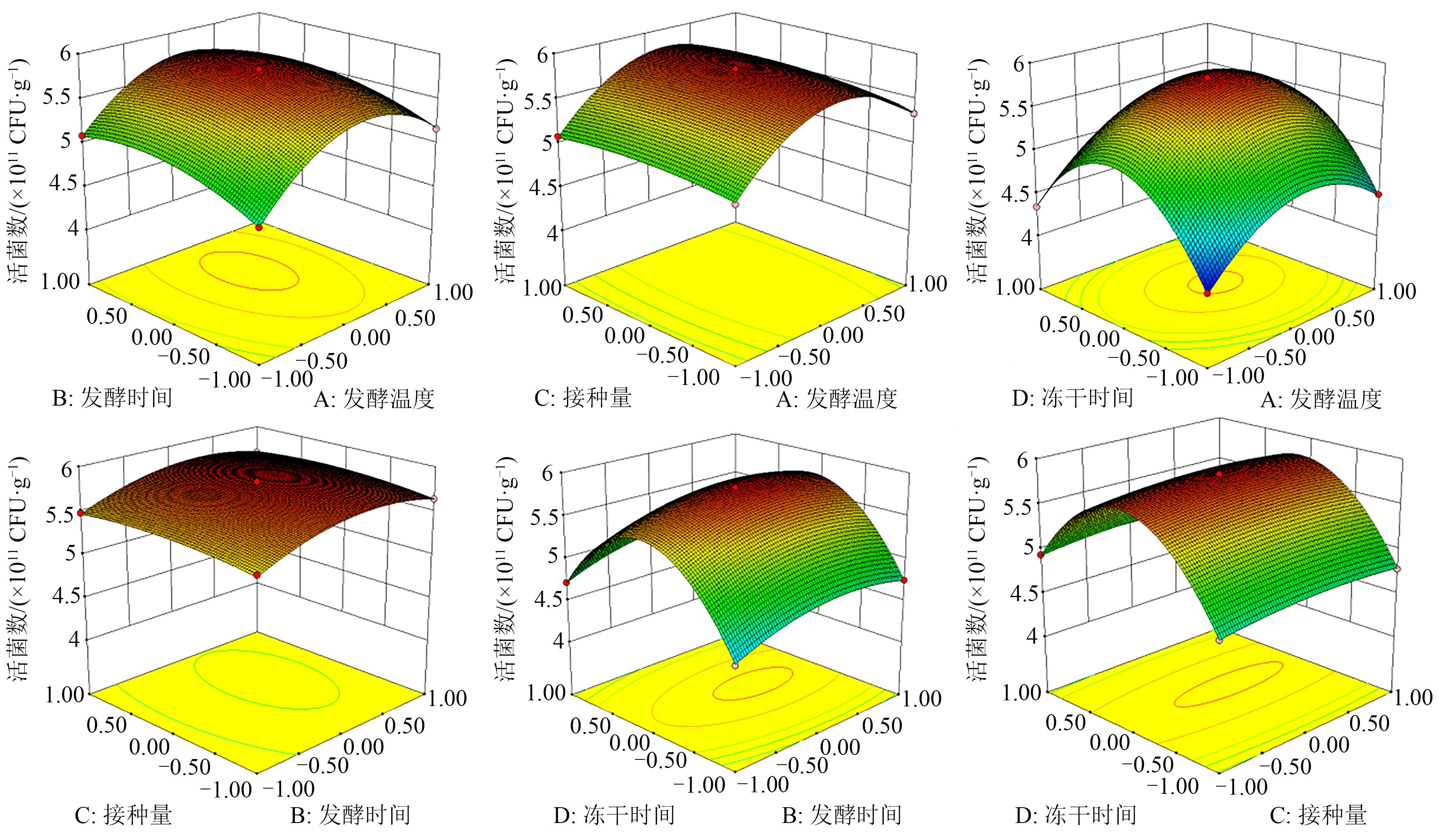

| 序号 | A:发酵温度/℃ | B:发酵时间/h | C:接种量/% | D:冻干时间/h | 活菌数/(×1011CFU·g-1) |

|---|---|---|---|---|---|

| 1 | 0 | 1 | 1 | 0 | 5.68 |

| 2 | 0 | 0 | 0 | 0 | 5.79 |

| 3 | 0 | -1 | 1 | 0 | 5.48 |

| 4 | 0 | -1 | -1 | 0 | 5.44 |

| 5 | 0 | 0 | 0 | 0 | 5.81 |

| 6 | 0 | 0 | -1 | -1 | 4.74 |

| 7 | 0 | 0 | -1 | 1 | 4.94 |

| 8 | -1 | 1 | 0 | 0 | 5.09 |

| 9 | 0 | -1 | 0 | -1 | 4.52 |

| 10 | 1 | -1 | 0 | 0 | 5.17 |

| 11 | 0 | 0 | 1 | 1 | 4.98 |

| 12 | 0 | 0 | 0 | 0 | 5.83 |

| 13 | 0 | 1 | 0 | -1 | 4.75 |

| 14 | 1 | 0 | 0 | -1 | 4.49 |

| 15 | 0 | 0 | 1 | -1 | 4.78 |

| 16 | 0 | 1 | -1 | 0 | 5.64 |

| 17 | 1 | 0 | 1 | 0 | 5.45 |

| 18 | -1 | 0 | 1 | 0 | 5.08 |

| 19 | 1 | 1 | 0 | 0 | 5.33 |

| 20 | 1 | 0 | -1 | 0 | 5.34 |

| 21 | -1 | 0 | 0 | 1 | 4.34 |

| 22 | 0 | 0 | 0 | 0 | 5.84 |

| 23 | 0 | -1 | 0 | 1 | 4.72 |

| 24 | 0 | 0 | 0 | 0 | 5.84 |

| 25 | 0 | 1 | 0 | 1 | 4.97 |

| 26 | 1 | 0 | 0 | 1 | 4.65 |

| 27 | -1 | 0 | 0 | -1 | 4.16 |

| 28 | -1 | -1 | 0 | 0 | 4.80 |

| 29 | -1 | 0 | -1 | 0 | 5.04 |

Table 4 Response surface test results

| 序号 | A:发酵温度/℃ | B:发酵时间/h | C:接种量/% | D:冻干时间/h | 活菌数/(×1011CFU·g-1) |

|---|---|---|---|---|---|

| 1 | 0 | 1 | 1 | 0 | 5.68 |

| 2 | 0 | 0 | 0 | 0 | 5.79 |

| 3 | 0 | -1 | 1 | 0 | 5.48 |

| 4 | 0 | -1 | -1 | 0 | 5.44 |

| 5 | 0 | 0 | 0 | 0 | 5.81 |

| 6 | 0 | 0 | -1 | -1 | 4.74 |

| 7 | 0 | 0 | -1 | 1 | 4.94 |

| 8 | -1 | 1 | 0 | 0 | 5.09 |

| 9 | 0 | -1 | 0 | -1 | 4.52 |

| 10 | 1 | -1 | 0 | 0 | 5.17 |

| 11 | 0 | 0 | 1 | 1 | 4.98 |

| 12 | 0 | 0 | 0 | 0 | 5.83 |

| 13 | 0 | 1 | 0 | -1 | 4.75 |

| 14 | 1 | 0 | 0 | -1 | 4.49 |

| 15 | 0 | 0 | 1 | -1 | 4.78 |

| 16 | 0 | 1 | -1 | 0 | 5.64 |

| 17 | 1 | 0 | 1 | 0 | 5.45 |

| 18 | -1 | 0 | 1 | 0 | 5.08 |

| 19 | 1 | 1 | 0 | 0 | 5.33 |

| 20 | 1 | 0 | -1 | 0 | 5.34 |

| 21 | -1 | 0 | 0 | 1 | 4.34 |

| 22 | 0 | 0 | 0 | 0 | 5.84 |

| 23 | 0 | -1 | 0 | 1 | 4.72 |

| 24 | 0 | 0 | 0 | 0 | 5.84 |

| 25 | 0 | 1 | 0 | 1 | 4.97 |

| 26 | 1 | 0 | 0 | 1 | 4.65 |

| 27 | -1 | 0 | 0 | -1 | 4.16 |

| 28 | -1 | -1 | 0 | 0 | 4.80 |

| 29 | -1 | 0 | -1 | 0 | 5.04 |

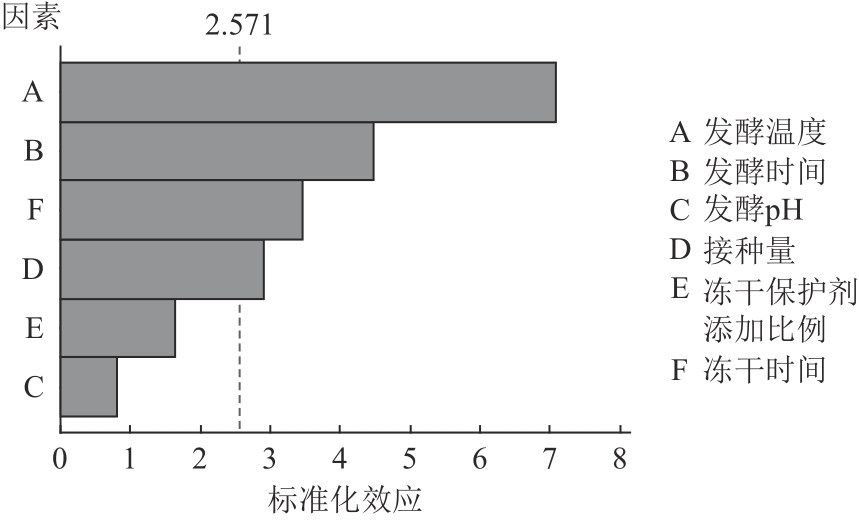

| 项目 | 平方和 | 自由度 | 均方 | F值 | P值 |

|---|---|---|---|---|---|

| 模型 | 6.73 | 14 | 0.48 | 1 344.61 | <0.000 1 |

| A-发酵温度 | 0.31 | 1 | 0.31 | 859.3 | <0.000 1 |

| B-发酵时间 | 0.15 | 1 | 0.15 | 412.33 | <0.000 1 |

| C-接种量 | 8.01×10-3 | 1 | 8.01×10-4 | 22.4 | 0.000 3 |

| D-冻干时间 | 0.11 | 1 | 0.11 | 313.66 | <0.000 1 |

| AB | 4.23×10-3 | 1 | 4.23×10-4 | 11.82 | 0.004 |

| AC | 1.23×10-3 | 1 | 1.23×10-4 | 3.43 | 0.085 4 |

| AD | 1.00×10-4 | 1 | 1.00×10-4 | 0.28 | 0.605 2 |

| BC | 0 | 1 | 0 | 0 | 1 |

| BD | 1.00×10-4 | 1 | 1.00×10-4 | 0.28 | 0.605 2 |

| CD | 0 | 1 | 0 | 0 | 1 |

| A2 | 1.79 | 1 | 1.79 | 5 020.01 | <0.000 1 |

| B2 | 0.25 | 1 | 0.25 | 688.16 | <0.000 1 |

| C2 | 0.032 | 1 | 0.032 | 88.27 | <0.000 1 |

| D2 | 5.12 | 1 | 5.12 | 14 323.47 | <0.000 1 |

| 残差 | 5.01×10-3 | 14 | 3.58×10-4 | — | — |

| 失拟项 | 3.13×10-3 | 10 | 3.13×10-4 | 0.66 | 0.726 9 |

| 纯误差 | 1.88×10-3 | 4 | 4.70×10-4 | — | — |

| 总离差 | 6.73 | 28 | — | — | — |

Table 5 Analysis of variance of regression model

| 项目 | 平方和 | 自由度 | 均方 | F值 | P值 |

|---|---|---|---|---|---|

| 模型 | 6.73 | 14 | 0.48 | 1 344.61 | <0.000 1 |

| A-发酵温度 | 0.31 | 1 | 0.31 | 859.3 | <0.000 1 |

| B-发酵时间 | 0.15 | 1 | 0.15 | 412.33 | <0.000 1 |

| C-接种量 | 8.01×10-3 | 1 | 8.01×10-4 | 22.4 | 0.000 3 |

| D-冻干时间 | 0.11 | 1 | 0.11 | 313.66 | <0.000 1 |

| AB | 4.23×10-3 | 1 | 4.23×10-4 | 11.82 | 0.004 |

| AC | 1.23×10-3 | 1 | 1.23×10-4 | 3.43 | 0.085 4 |

| AD | 1.00×10-4 | 1 | 1.00×10-4 | 0.28 | 0.605 2 |

| BC | 0 | 1 | 0 | 0 | 1 |

| BD | 1.00×10-4 | 1 | 1.00×10-4 | 0.28 | 0.605 2 |

| CD | 0 | 1 | 0 | 0 | 1 |

| A2 | 1.79 | 1 | 1.79 | 5 020.01 | <0.000 1 |

| B2 | 0.25 | 1 | 0.25 | 688.16 | <0.000 1 |

| C2 | 0.032 | 1 | 0.032 | 88.27 | <0.000 1 |

| D2 | 5.12 | 1 | 5.12 | 14 323.47 | <0.000 1 |

| 残差 | 5.01×10-3 | 14 | 3.58×10-4 | — | — |

| 失拟项 | 3.13×10-3 | 10 | 3.13×10-4 | 0.66 | 0.726 9 |

| 纯误差 | 1.88×10-3 | 4 | 4.70×10-4 | — | — |

| 总离差 | 6.73 | 28 | — | — | — |

| 组别 | OD600 | 抑菌圈直径/mm | 幽门螺杆菌抑制率/% |

|---|---|---|---|

| 空白对照 | — | 0 | 0 |

| 阳性对照 | — | 20.92±1.02** | 100.00** |

| 菌悬液 | 1.911 | 16.48±2.14** | 78.78** |

| 发酵上清液 | 0.253 | 14.55±0.84** | 69.55** |

Table 6 Bacteriostatic rate of fermentation supernatant and bacterial suspension of Lactiplantibacillus plantarum HCS03-001

| 组别 | OD600 | 抑菌圈直径/mm | 幽门螺杆菌抑制率/% |

|---|---|---|---|

| 空白对照 | — | 0 | 0 |

| 阳性对照 | — | 20.92±1.02** | 100.00** |

| 菌悬液 | 1.911 | 16.48±2.14** | 78.78** |

| 发酵上清液 | 0.253 | 14.55±0.84** | 69.55** |

| 1 | SAVOLDI A, CARRARA E, GRAHAM D Y, et al.. Prevalence of antibiotic resistance in Helicobacter pylori: a systematic review and meta-analysis in World Health Organization regions[J]. Gastroenterology, 2018, 155(5): 1372-1382. |

| 2 | LOSURDO G, CUBISINO R, BARONE M, et al.. Probiotic monotherapy and Helicobacter pylori eradication: a systematic review with pooled-data analysis[J]. World J. Gastroenterol., 2018, 24(1): 139-149. |

| 3 | 刘昆梅,刘宏鹏,郭乐.幽门螺杆菌ATCC 43504感染BALB/c小鼠动物胃炎模型的建立及分析[J].生物技术进展,2015,5(6):446-450. |

| LIU K M, LIU H P, GUO L. Establishment and analysis of gastritic model of Helicobacter pylori ATCC 43504 infection in BALB/c mice[J]. Curr. Biotechnol., 2015, 5(6): 446-450. | |

| 4 | 陈霞,夏晨梅,戴再友,等.十二指肠溃疡中幽门螺杆菌定植与菌群结构的关系[J].生物技术进展,2019,9(5):536-542. |

| CHEN X, XIA C M, DAI Z Y, et al.. The relationship between Helicobacter pylori colonization and duodenal flora structure in duodenal ulcer[J]. Curr. Biotechnol., 2019, 9(5): 536-542. | |

| 5 | MESTRE A, SATHIYA N R, RIVAS D, et al. Role of probiotics in the management of Helicobacter pylori [J/OL]. Cureus, 2022, 14(6): e26463 [2023-09-21]. . |

| 6 | 朱红梅,刘颖初,薛元,等.2012-2022年中国幽门螺杆菌流行病学Meta分析[J].预防医学情报杂志,2023,39(9):1124-1137. |

| ZHU H M, LIU Y C, XUE Y, et al.. Meta-analysis of epidemiology of Helicobacter pylori infection in China from 2012 to 2022[J]. J. Prev. Med. Inf., 2023, 39(9): 1124-1137. | |

| 7 | PENUMETCHA S S, AHLUWALIA S, IRFAN R, et al.. The efficacy of probiotics in the management of Helicobacter pylori: a systematic review[J/OL]. Cureus, 2021, 13(12): e20483[2023-09-22]. . |

| 8 | CHEY W D, LEONTIADIS G I, HOWDEN C W, et al.. ACG clinical guideline: treatment of Helicobacter pylori infection[J]. Am. J. Gastroenterol., 2017, 112(2): 212-239 |

| 9 | JI J, YANG H. Using probiotics as supplementation for Helicobacter pylori antibiotic therapy[J/OL]. Int. J. Mol. Sci., 2020, 21(3): 1136[2023-09-21]. . |

| 10 | QURESHI N, LI P, GU Q. Probiotic therapy in Helicobacter pylori infection: a potential strategy against a serious pathogen?[J]. Appl. Microbiol. Biotechnol., 2019, 103(4): 1573-1588. |

| 11 | BATDORJ B, TRINETTA V, DALGALARRONDO M, et al.. Isolation, taxonomic identification and hydrogen peroxide production by Lactobacillus delbrueckii subsp. lactis T31, isolated from Mongolian yoghurt: inhibitory activity on food-borne pathogens fool-borne pathogens[J]. J. Appl. Microbiol., 2007, 103(3): 584-593. |

| 12 | BAI X, ZHU M, HE Y, et al.. The impacts of probiotics in eradication therapy of Helicobacter pylori [J/OL]. Arch. Microbiol., 2022, 204(12): 692[2023-09-22]. . |

| 13 | 汪海涛,汤纯,闵祥博,等.植物乳杆菌HCS03-001对龋病防治作用研究[J].中国乳品工业,2023,51(8):20-24. |

| WANG H T, TANG C, MIN X B, et al.. Prevention and treatment effect on dental caries of Lactobacillus plantarum HCS03-001[J]. China Dairy Ind., 2023, 51(8): 20-24. | |

| 14 | 宋佳,余萍,矫艳平,等.具有缓解口臭效果的植物乳杆菌HCS03-001对食品防腐剂的耐受性研究[J].中国食品添加剂,2022,33(11):113-117. |

| SONG J, YU P, JIAO Y P, et al.. Tolerance to food preservatives of Lactobacillus plantarum HCS03-001 with halitosis relieving effect[J]. China Food Addit., 2022, 33(11): 113-117. | |

| 15 | 陈雪,矫艳平,余萍,等.植物乳杆菌HCS03-001对小鼠功能性便秘及肠道菌群的影响[J].中国酿造,2022,41(1):55-58. |

| CHEN X, JIAO Y P, YU P, et al.. Effect of Lactobacillus plantarum HCS03-001 on functional constipation and intestinal flora in mice[J]. China Brew., 2022, 41(1): 55-58. | |

| 16 | 矫艳平,余萍,赵迪,等.植物乳杆菌HCS03-001安全性评价及其益生特性分析[J].食品工业科技,2022,43(5):165-171. |

| JIAO Y P, YU P, ZHAO D, et al.. Safety evaluation and probiotic characteristics analysis of Lactobacillus plantarum HCS03-001[J]. Sci. Technol. Food Ind., 2022, 43(5): 165-171. | |

| 17 | 周宇朦.维生素K2菌株的选育及高效发酵技术的研究[D].沈阳:沈阳农业大学,2020. |

| 18 | 张立华,王一樊,张旭阳,等.响应面分析法优化酶法提取红景天苷的工艺研究[J].生物技术进展,2023, 3(3):441-448. |

| ZHANG L H, WANG Y F, ZHANG X Y, et al.. Optimization of enzymatic extraction process of salidroside by response surface analysis[J]. Curr. Biotechnol. 2023, 13(3): 441-448. | |

| 19 | 管爱星,黄玉存,黄干荣,等.益生菌的不同组合体外抗幽门螺杆菌作用的实验研究[J].右江民族医学院学报,2023,45(2):208-212+217. |

| GUAN A X, HUANG Y C, HUANG G R, et al.. Experimental study on anti-helicobacter pylori effect of different combinations of probiotics in vitro[J]. J. Youjiang Med. Univ. Natl., 2023, 45(2): 208-212+217. | |

| 20 | 张美怡,翟齐啸,赵建新,等.鼠李糖乳杆菌JS-SZ-2-1抗幽门螺杆菌感染的临床效果评价[J].食品与发酵工业,2020,46(23):29-34. |

| ZHANG M Y, ZHAI Q X, ZHAO J X, et al.. Clinical efficacy evaluation of Lactobacillus rhamnosus JS-SZ-2-1 against Helicobacter pylori infection[J]. Food Ferment. Ind., 2020, 46(23): 29-34. |

| [1] | Xiaojing GAO, Zhulan ZHANG, Xianju LIN, Guanrong QIU, Yaoming WEN, Jianhui FAN, Hongxiang HUANG. Optimization of Fermentation Culture Conditions for Cyclosporine A Using Response Surface Method [J]. Current Biotechnology, 2025, 15(3): 518-525. |

| [2] | Siyuan QIU, Jingxue XU, Yiting ZHANG, Shengyang SUN, Dongxue SHENG, Jiaxin GAO, Lina QU. Screening and Condition Optimization of Endogenous Compound Microflora in Shale Oil Driven by Biological Fracturing Fluid [J]. Current Biotechnology, 2025, 15(2): 305-313. |

| [3] | Hongbo FAN, Liangyong HU, Songqing HU. Establishment of Digital PCR Detection System for Helicobacter pyloriureC and 23S rDNA [J]. Current Biotechnology, 2024, 14(5): 868-874. |

| [4] | Jia SONG, Xuelong LI, Xinmei LIN, Ping YU, Sicheng YANG, Yongzhen PENG, Yanping JIAO, Xuejiao CHEN. Study on Optimization of Culture Method and Improvement of Sleep Function of Limosilactobacillus reuteri HCS02-001 [J]. Current Biotechnology, 2024, 14(1): 133-140. |

| [5] | Lihua ZHANG, Yifan WANG, Xuyang ZHANG, Qianying LIU, Siqi GAO, Jian JIAO. Optimization of Enzymatic Extraction Process of Salidroside by Response Surface Analysis [J]. Current Biotechnology, 2023, 13(3): 441-448. |

| [6] | Lei LIU, Xinyue ZHOU, Zhen ZHU, Ye CAO, Wenbin WANG. Prokaryotic Expression of Outer Membrane Ferritin Receptor pvuA Gene of Vibrio parahaemolyticus and Optimization of Induction Conditions for Product [J]. Current Biotechnology, 2022, 12(3): 396-404. |

| [7] | ZHANG Hongbing, LIU Hui, SHI Xiuying, LI Huixuan, FAN Daochun. Microalgae Breeding with High Efficient of Oil-producing and Optimization of Cultivation Conditions [J]. Curr. Biotech., 2020, 10(3): 311-319. |

| [8] | WANG Yingyan, CHEN Wenna*, JIA Cunjiang, FANG Shubiao, QIN Bin, ZHU Zhengqiao. Study on Fermentation Process of Lycopene Production [J]. Curr. Biotech., 2020, 10(3): 320-327. |

| [9] | QIU Guanyu, LI Weijie*, LIU Baolin. Study on Reducing the Concentration of Dimethyl Sulfoxide in Hepatocyte Cryoprotectant by Response Surface Methodology [J]. Curr. Biotech., 2020, 10(2): 185-189. |

| [10] | SHI Jiangchuan1,2, SHI Jia2*, YU Mingxiao2, ZHAO Weixue2, XU Hao2, XU Lei2. Optimization of Spray Drying Technology for Hemp Seed Oil Microcapsules by Response Surface Methodology [J]. Curr. Biotech., 2020, 10(2): 198-204. |

| [11] | HU Qinhan, WANG Wei, LUO Yingbiao, DU Fang, YANG Liuqing, ZHAO Ting* . Optimization of Ultrasonic Assisted Enzymatic Extraction of Polysaccharide from Kadsura longipedunculata by Response Surface Analysis [J]. Curr. Biotech., 2018, 8(4): 351-357. |

| [12] | ZHENG Daheng1,2, WANG Wei2, LI Qian2, CHEN Yao3, ZHANG Weijie2, ZHAO Ting4, YANG Liuqing4*. Optimization on Extraction Technology of Polysaccharides from Hibiscus sabdariffa by Response Surface Methodology and Evaluation of its Antioxidant Activity [J]. Curr. Biotech., 2018, 8(2): 161-168. |

| [13] | ZHENG Wei1,2, ZHOU Yinghong3, LIU Jinlong4*. Response Surface Optimization of the Fermentation Process of Cordycepin by Paecilomyces varioti A20140822 [J]. Curr. Biotech., 2017, 7(6): 625-631. |

| [14] | DENG Chunmeng1, LI Qian2, WANG Wei2, ZHANG Weijie2, YU Ping3, MAO Guanghua1*, ZHAO Ting3, FENG Weiwei1, YANG Liuqing3, WU Xiangyang1*. Optimization of Extraction of Water-soluble Selenium-containing Protein from Se-enriched Maitake by Response Surface Methodology [J]. Curr. Biotech., 2017, 7(3): 247-252. |

| [15] | REN Hong-mei, LIU Zuo-jun*, WU Guo-qiang, SHAN Xi-wen. Study on CMCase Production of Trichoderma W2 by Solid-state Fermentation [J]. Curr. Biotech., 2013, 3(4): 270-276. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||